Adoption projects_

What we do?

Adoption Services

01

DfAM & EfAM

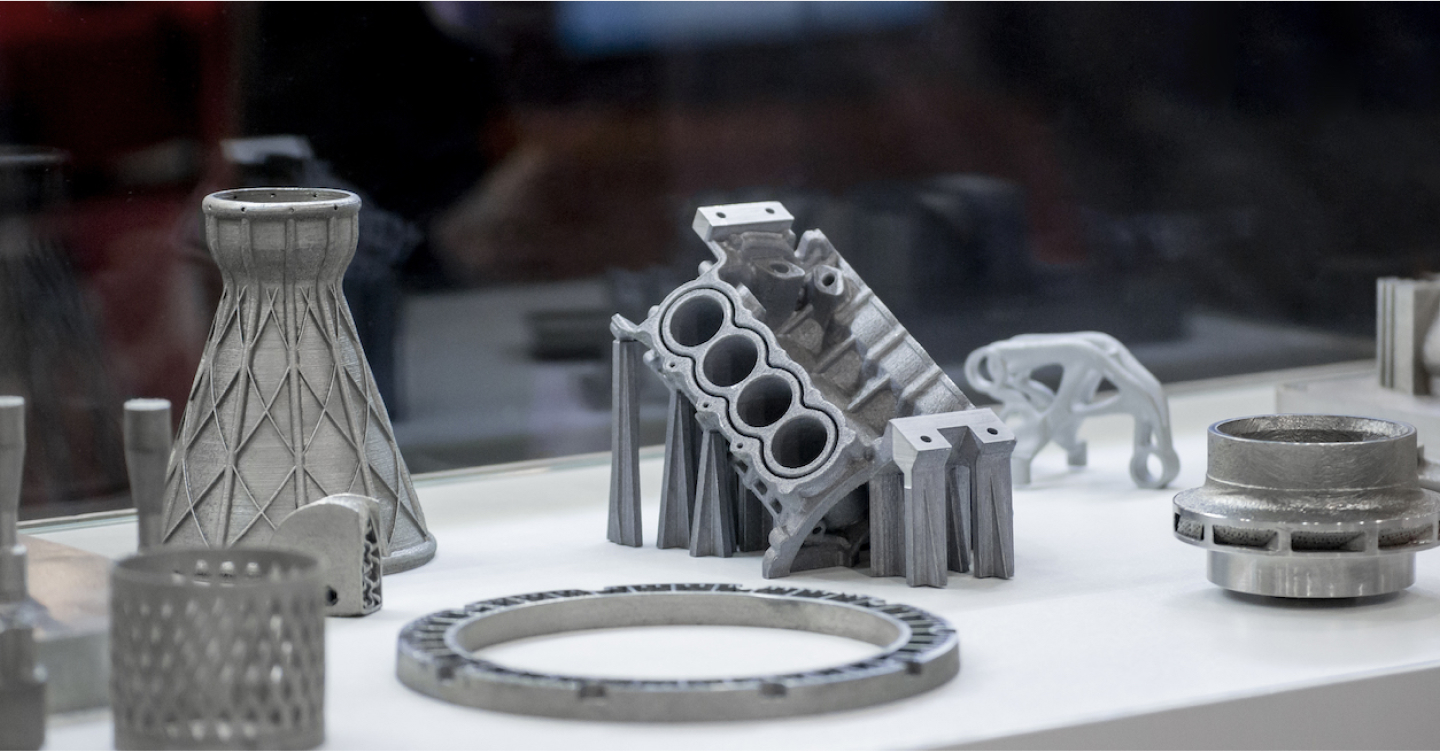

Design and Engineering for Additive Manufacturing is the key expertise to take the most advantatge of using AM/3DP technologies. Design freedom to create innovative applications with advanced functionalities...

Parametric Design, Computational Design, Lattice Structures, Topology Optimization, Generative Design.

02

Business

Guiding your management and technical team to detect 3DP transformation opportunities. And helping also to design the best economical strategy for technology implementation.

Opportunities detection, Business assessment, Econonical justification ROI analisys, Technology usage scale-up, Funding opportunities search.

03

Training

Enabling your company and employees to get used with 3DP technologies, Design, Engineering, Production control, Machine operation or other necessary skills

DfAM & EfAM, Design for especific technology, Build preparation, supports generation & optimization, Machine control & operation.

Adoption Projects

01

E2E Solutions

02

Experiment & Test

03

Test before invest

Ostomy Interfaces

A reusable wafer for any stoma shape, eliminating leaks in two-piece Ostomy Pouches.

Powered by:

Inflatable Wheelchair Cushion

Redesign and 3D printing of the pneumatic system of the Nubolo cushion to improve comfort.

Powered by:

Water Pipes Inspection Camera

Efficient water pipe inspection solution through additive manufacturing technology.

Powered by:

E-Miles L7e

A Revolutionary 3D Printed Electric Car

Powered by: